Titanium felt is a common product in the metal fiber industry and is used in a wide variety of applications. Titanium fibers can be scraped from wires, scraped from foils, drawn from larger diameter wires, processed from ingots and cast from molten metal.

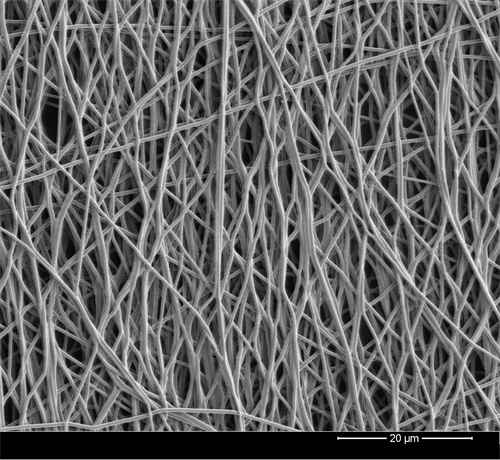

Titanium felt mats are made by a special lay-up process and a special ultra-high temperature vacuum sintering process. Compared with titanium powder sintered plate, titanium fiber felt has excellent three-dimensional mesh, porous structure, high porosity, large specific surface area, uniform pore size distribution, pressure resistance, corrosion resistance is particularly good, can be rolled and processed. Titanium fiber felt is widely used in foreign countries in the military, aerospace, civil, medical and other industries.

Titanium felt mats are mainly used in electrolysis tanks as flow field or diffusion materials, especially on the oxygen (anode) side.

Titanium fiber characteristics

1.Low cost

2.High capacity

3.Customized length

The application areas of titanium fiber are as follows:

1.High temperature gas filtration

2.Emission particulate filtration

3.Medical supports

4.Environmental industry

Titanium Fiber Mat Specifications

| Thickness | Filter Rating | Porosity |

| mm | um | % |

| 0.3 | 5 | 75 |

| 0.3 | 7 | 75 |

| 0.38 | 10 | 75 |

| 0.4 | 15 | 79 |

| 0.48 | 20 | 80 |

| 0.62 | 25 | 80 |

| 0.62 | 30 | 80 |

| 0.68 | 40 | 78 |

| 0.62 | 60 | 85 |