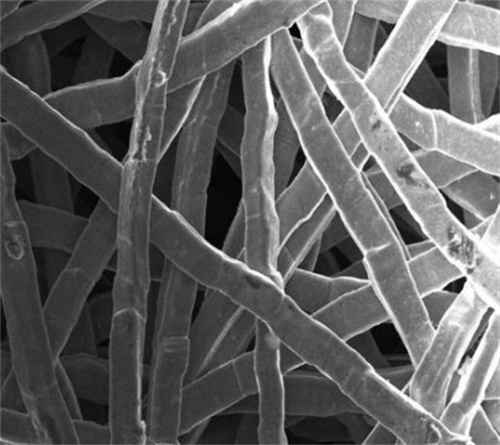

Titanium felt is a material with special pore structure, and its pore structure and size parameters have an important influence on its performance. In this paper, we will discuss the two aspects of pore structure and size parameters.

The pore structure of titanium felt has an important influence on its performance. The pore structure of titanium felt mainly includes pore diameter, porosity and pore distribution. Pore diameter refers to the size of pores, porosity refers to the proportion of pores occupying the entire volume of the material, and pore distribution refers to the distribution of pores in the material. Different combinations of these parameters will result in titanium mats with different properties. For example, titanium felts with smaller pore size and lower porosity have higher strength and stiffness, but poorer air permeability: titanium felts with larger pore size and higher porosity have better air permeability, but lower strength and stiffness. Therefore, when selecting a titanium felt, its pore structure needs to be determined according to the specific application scenario.

The dimensional parameters of titanium felts also have an important influence on their performance. The dimensional parameters of titanium felts mainly include thickness, length and width. Thickness refers to the thickness of the mantle felt, and length and width refer to the length and width of the chin drill. Different combinations of these parameters will result in titanium felts with different propertiesFor example, a thicker chin drill has higher strength and stiffness, but poorer air permeability:Titanium felts with a larger length and width have a larger surface area and are suitable for application scenarios such as adsorption and filtration. Therefore, when selecting titanium felts, it is necessary to determine their size parameters according to specific application scenarios.

The pore structure and size parameters of titanium felts have an important influence on their performance. When selecting titanium felts, it is necessary to determine the pore structure and size parameters according to the specific application scenario in order to achieve the best performance.

As a leading manufacturer of titanium GDL. The quality of titanium felts produced by Ruichuang is guaranteed.Our company can customize the production of titanium fiber mats of various specifications and performance according to customer requirements.If you need titanium felts, please contact us.