When choosing a high-quality Titanium Fiber Felt for PEM manufacturer, you need to consider many aspects such as technical ability, product quality, production capacity, certification qualification and so on. The following are the specific guidelines for choosing a factory:

- Technical capability and R&D level

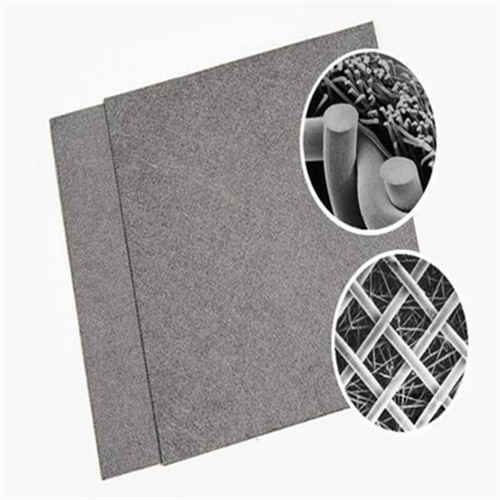

Material and manufacturing process: The production technology of Titanium Fiber Felt for PEM is demanding, especially the sintering of titanium fibres and the control of porous structure. High-quality manufacturers usually have mature sintering processes and advanced equipment to produce Titanium Fiber Felt for PEM with uniform porosity and stable performance.

R&D strength: Highly qualified R&D teams can continuously optimise the performance of Titanium Fiber Felt for PEM, such as improving electrical conductivity, corrosion resistance, etc., to meet the needs of emerging applications. Check whether the manufacturer has a professional R&D team and technical experts, as well as its technical patents in titanium material-related fields.

- Product quality

Stability of performance: A quality Titanium Fiber Felt for PEM should have stable porosity, conductivity and permeability to ensure that it performs well under different environmental conditions (e.g., high temperature, high pressure).

Raw material quality: Find out if the manufacturer uses high-purity titanium materials, as high-purity titanium can significantly improve the corrosion resistance and service life of the product.

Quality control: High-quality manufacturers usually implement strict quality control processes, including factory testing, durability testing and performance consistency testing, to ensure the quality of each batch of products.

- Production scale and delivery capacity

Production capacity and delivery time: manufacturers with large production capacity and short delivery time have more advantages, especially in the case of large demand, to ensure on-time delivery. Choose manufacturers with batch production capacity and strong delivery capability.

Advanced equipment: Check whether the manufacturer’s production equipment is advanced, especially in fibre weaving, laying and sintering. Automated equipment can increase capacity, reduce human error and improve product consistency.

- Certification qualification

Quality management system certifications: e.g., ISO 9001, ISO 14001. Manufacturers with these certifications usually have well-established quality management systems and environmental management systems.

Application-related certifications: If the Titanium Fiber Felt for PEM is used in a specific industry (e.g., military, aerospace, or medical), you need to check whether the manufacturer has the appropriate certifications. These certifications show the applicability and safety of the manufacturer’s products in specific applications.

- Industry reputation and customer feedback

Customer reputation: You can learn how the manufacturer’s products perform in the market through customer feedback and evaluation. High-quality manufacturers usually have good customer reviews and long-term customer relationships.

Industry reputation: You can learn about the manufacturer’s industry reputation through industry forums, exhibitions and upstream and downstream of the supply chain, and select manufacturers with a good reputation in the industry.

- After-sales service and technical support

Technical support: The application of Titanium Fiber Felt for PEM has high technical requirements, and high-quality manufacturers usually provide strong technical support to assist customers in solving technical problems in product installation, commissioning and maintenance.

After-sales service: Choose manufacturers with good after-sales service to ensure that product problems can be resolved in a timely manner.

- Price and cost-effective

Reasonable cost: The cost of high quality Titanium Fiber Felt for PEM is relatively high, but its performance and durability are better, reducing the frequency of replacement and maintenance costs in long-term use.

Cost-effective: While focusing on the price, it is also important to examine its cost-effectiveness and choose those manufacturers who have achieved a balance between performance, quality and price.

- Product application cases

Case study: Quality manufacturers usually have mature application cases. You can confirm the performance of the manufacturer’s Titanium Fiber Felt for PEM in practical applications, including its effectiveness in fuel cells, hydrogen production by water electrolysis, filtration and so on, by understanding these cases.

Conclusion

Choosing a high-quality Titanium Fiber Felt for PEM manufacturer requires comprehensive consideration of the above aspects. It is recommended to further validate through site visits, testing samples, and consulting customer reviews to ensure that the Titanium Fiber Felt for PEM manufacturer you choose can stably provide high-quality products and perfect services.