When customizing Titanium Fiber Felt for PEM, there are a number of key parameters and requirements that need to be provided to ensure that the product will meet the specific application requirements. Below are some of the key aspects that need to be accounted for when customizing Titanium Fiber Felt for PEM:

- Material Selection

Types of Titanium Alloys: Common materials used for Titanium Fiber Felt for PEM include pure titanium (Grade 1, Grade 2) or titanium alloys (e.g. Grade 5, Grade 7, etc.). Different titanium alloys have different characteristics in terms of strength, toughness, corrosion resistance, temperature resistance, etc. Choosing the right material is critical to the life and performance of Titanium Fiber Felt for PEM.

Surface Coating: If needed, you can choose to coat the surface of Titanium Fiber Felt for PEM with catalysts (such as platinum, iridium and other precious metals) or other protective coatings to enhance its electrochemical performance or corrosion resistance.

- Specifications and Dimensions

Thickness: The thickness of Titanium Fiber Felt for PEM usually ranges from 0.25mm to 1mm and can be customized upon request. Choosing the right thickness has a significant impact on gas-liquid mass transfer performance, electrical conductivity, and mechanical strength.

Porosity: Porosity directly affects the permeability, permeability, and gas-liquid mass transfer properties of Titanium Fiber Felt for PEM. A range of porosity (e.g., 60%-70%) is often specified to meet the requirements of different applications.

Dimensions: Provide the specific dimensions of Titanium Fiber Felt for PEM, such as length, width, and shape (e.g. square, round, or other customized shapes), common sizes are 5×5 cm, 10×10 cm, 20×20 cm, etc. Special sizes can be customized according to the customer’s needs.

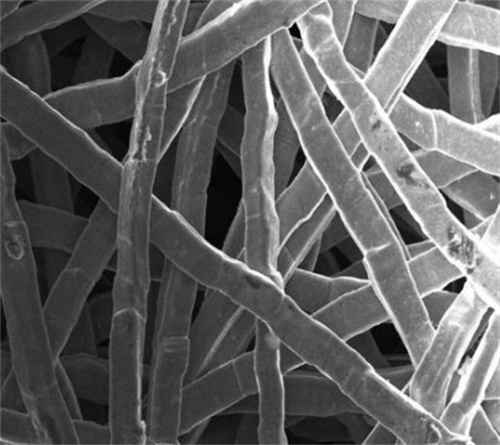

- Pore size distribution and fiber diameter

Pore size distribution: Specify the pore size or distribution range (e.g. 30-60 μm). Pore size and uniformity are very critical for gas diffusion, electrolysis efficiency, liquid penetration, etc.

Fiber Diameter: The diameter size of the titanium fibers determines the mechanical strength and structural stability of the Titanium Fiber Felt for PEM, which is usually in the micron scale (e.g.: 30-60μm).

- Pore structure

Three-dimensional mesh structure: Titanium Fiber Felt for PEM is typically constructed with a three-dimensional mesh structure to optimize gas-liquid mass transfer. When customizing, it is necessary to specify whether this type of structure is used or whether a specific weaving process is required.

Surface roughness: In some applications, surface roughness is critical for adhesion or stability of the catalytic layer, and it is necessary to specify whether additional surface treatments such as pickling, etching or other surface enhancements are required.

- Performance requirements

Electrochemical properties: For example, does Titanium Fiber Felt for PEM need to have a specific conductivity or be adapted to a specific electrolytic process (e.g., water electrolysis for hydrogen production). In this case, precious metal plating or treatment on the surface of the Titanium Fiber Felt for PEM may be required.

Corrosion resistance: Identify the chemical environment that Titanium Fiber Felt for PEM will be subjected to, such as whether it will be used in an environment with strong acids, bases, or other corrosive gases, and ensure that its corrosion resistance meets the requirements.

High temperature resistance: If Titanium Fiber Felt for PEM is used in high temperature environments (e.g., high temperature electrolysis, fuel cells, etc.), the required temperature range needs to be specified.

- Application Areas

Hydrogen electrolysis: If Titanium Fiber Felt for PEM is to be used as an anode gas diffusion layer, Membrane Electrode Assembly (MEA), or other components in PEM water electrolysis for hydrogen production, the type of application needs to be specified to ensure a performance match.

Fuel Cells: If used in hydrogen fuel cells, air batteries, etc., the type of battery, operating environment and other requirements need to be specified.

Other applications: Titanium Fiber Felt for PEM can also be used in other industrial fields, such as aerospace, medical, marine and so on. The requirements of different fields will affect the customized specifications and performance.

- Manufacturing process and quality control

Sintering process: The sintering process of Titanium Fiber Felt for PEM is very important. Specify the required sintering temperature, sintering time, and environmental conditions (e.g., vacuum sintering or atmosphere sintering) to ensure the denseness and strength of the material.

Surface treatment: Specify whether surface treatment steps such as pickling, plating (e.g., platinum, iridium plating), plasma cleaning, etc., are required to improve the electrochemical activity or corrosion resistance of the Titanium Fiber Felt for PEM.

Quality control: The required quality standards, such as porosity, pore size distribution, surface finish, etc., need to be specified, as well as how to carry out inspection and acceptance.

- Quantity and delivery time

Customized quantity: Specify the quantity of Titanium Fiber Felt for PEM required, which will affect the production cycle and cost.

Delivery time: According to the production cycle and customer’s demand, confirm the delivery time and whether there is a need for rush order.

- Cost control and budget

Cost requirements: Control the production specifications and manufacturing process of Titanium Fiber Felt for PEM according to the requirements and budget, whether to choose higher grade titanium alloy or to add precious metal coating, etc.

Summary

When customizing Titanium Fiber Felt for PEM, it is important to detail specific requirements in terms of material, specifications, porosity, surface finish, performance requirements, application areas, manufacturing processes, etc. Specifying these details helps ensure that Titanium Fiber Felt for PEM products will maximize application requirements, provide excellent performance and long service life.