Choosing a good Titanium Fiber Felt for PEM manufacturer is critical to ensure product quality and performance as required.Below are a few important criteria and considerations for selecting a quality Titanium Fiber Felt for PEM manufacturer:

- Technical capability and production process

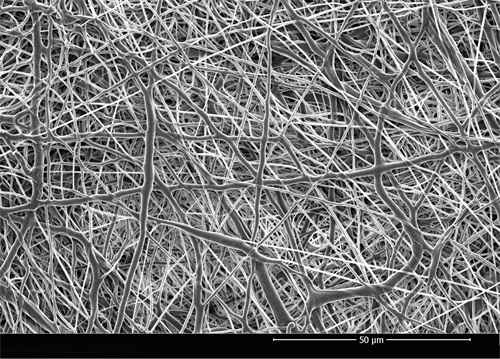

Advanced production technology: Choose a manufacturer with advanced production technology, such as high-precision sintering technology, titanium fiber braiding technology, coating technology, etc., to ensure that the structure and performance of Titanium Fiber Felt for PEM meet the standards.

Patents and technology certifications: Check whether the manufacturer’s technology is protected by patents and whether it has passed international certifications (e.g., ISO 9001, ISO 14001, etc.), which can guarantee the quality and sustainability of the product.

Production equipment and process: Find out the type of equipment and technology level used by the manufacturer, and whether it has the ability to meet mass production, high-precision requirements and customized production.

- Product quality control

Strict quality control system: Ensure that the manufacturer has a complete quality control process that strictly monitors all aspects of the process, from raw materials to the production process to the finished product. High-quality manufacturers usually have perfect testing methods, can carry out porosity, conductivity, corrosion resistance and other key performance tests.

Quality inspection report: Choose a manufacturer that can provide detailed quality inspection reports, especially on the porosity, thickness, and strength of Titanium Fiber Felt for PEM. This helps to ensure that the product meets your needs.

Experienced technical team: The technical team is experienced and has certain R&D capability, which can provide technical support and customized solutions.

- Production capacity and delivery time

Production scale and capacity: Understand the production scale and capacity of the manufacturer to ensure that it can meet your order requirements. Especially for large orders, the stability of production capacity is very critical.

Delivery reliability: Reliable delivery lead time is one of the important criteria for evaluating a manufacturer. Find out if the manufacturer’s lead time is flexible and can deliver on time, especially for customized Titanium Fiber Felt for PEM.

Customization capability: Some projects may require specific specifications of Titanium Fiber Felt for PEM, and it is important that the manufacturer has the customization capability to meet these special needs. A quality manufacturer will offer a wide range of specifications, sizes and customization.

- Technical support and after-sales service

Technical Support: A good Titanium Fiber Felt for PEM manufacturer can usually provide technical consultation, production process support and solutions. This is essential to ensure that the product can be matched to your application needs.

After-sales service: Whether the manufacturer provides perfect after-sales service, including product quality problems, technical support, long-term maintenance and updates. If quality problems occur, whether the after-sales service is timely and effective is also very important.

- Industry reputation and customer evaluation

Industry reputation: to understand the manufacturer’s industry reputation, you can check the network evaluation, customer feedback and other ways. Manufacturers who have cooperated with many large enterprises or industry leaders for a long time can usually provide more reliable products and services.

Customer Cases: Check the manufacturer’s success stories, especially the experience of working with large, well-known customers. These cases can help you assess the manufacturer’s technical level and product stability.

Customer visits and feedback: you can contact the manufacturer’s existing customers to learn about their experience and feedback, which helps to more fully understand the manufacturer’s strengths and weaknesses.

- Price and cost-effectiveness

Cost Effectiveness: The price of Titanium Fiber Felt for PEM products should be measured based on the material, production process, and performance requirements. When choosing, the balance of product quality, performance and price should be considered comprehensively.

Long-term cooperation cost: In addition to the single purchase price, the cost-effectiveness of long-term cooperation should also be taken into account. For example, the availability of discounts, regular supply, bulk purchase discounts, etc.

- Environmental protection and sustainability

Environmentally friendly production: The environmental requirements in the production process of Titanium Fiber Felt for PEM is an important consideration. Choosing a manufacturer that complies with environmental regulations and uses non-hazardous materials and production processes can reduce the impact on the environment.

Sustainability: High-quality manufacturers usually adopt energy-saving and emission reduction measures in production, and consider the recycling and reuse of products to ensure that the production process meets the requirements of sustainable development.

- Geographic location and logistics

Geographic location: whether the area where the manufacturer is located is convenient to your transportation routes, especially for international orders, the proximity of the supplier to the port also affects the convenience and cost of delivery.

Logistics capability: whether the logistics management capability of the manufacturer is efficient and able to ensure that the products are delivered safely and on time within the stipulated time.

Summarize:

Choosing a quality Titanium Fiber Felt for PEM manufacturer requires a comprehensive consideration of the following factors: technical capability and production process, product quality control, production capacity and delivery lead time, technical support and after-sales service, industry reputation and customer evaluation, price and cost-effectiveness, environmental protection and sustainability, as well as geographic location and logistics. Through comprehensive evaluation, you can choose a high quality Titanium Fiber Felt for PEM manufacturer that best suits your needs.