A new joint report by the International Renewable Energy Agency (IRENA) and the European Patent Office (EPO) shows that innovations in electrolysis technology are accelerating the reduction in the cost of renewable hydrogen production.

Why we need to accelerate the innovation of electrolysis technology?

As more and more countries pursue deep decarbonization strategies, hydrogen produced from renewable energy sources using electrolytic water is expected to be at the heart of the energy transition. And a key part of the solution to the clean energy puzzle.

IRENA’s 1.5°C scenario predicts that hydrogen and its derivatives produced on the basis of renewable energy sources will account for 12% of final energy consumption by 2050. Several countries have explicitly included electrolyzer capacity deployment targets in their national hydrogen strategies.

Therefore, in order to cope with the growing demand for green hydrogen, a significant increase in electrolyzer capacity and expansion of the electrolyzer market are required.

How to reward electrolyzer system costs?

Cost reductions in electrolyzer systems are critical to improving the competitiveness of renewable hydrogen, and technological innovation is key to achieving this goal.

According to IRENA, investment costs for electrolyzer plants can be reduced by 40 percent in the short term and 80 percent. In the long term through key strategies such as improved electrolyzer design and construction, economies of scale, replacement of scarce precious metal materials with metals that are abundant in reserves, and increased operational efficiency and flexibility.

EPO and IRENA recently released a new patent insight report on innovation trends in electrolyzer hydrogen production. The report uses patent statistics to reveal trends and developments in the field of electrolytic hydrogen production from renewable energy sources. Helping policymakers, technologists, companies and investors to better understand these rapidly expanding technology areas through charts and commentary.

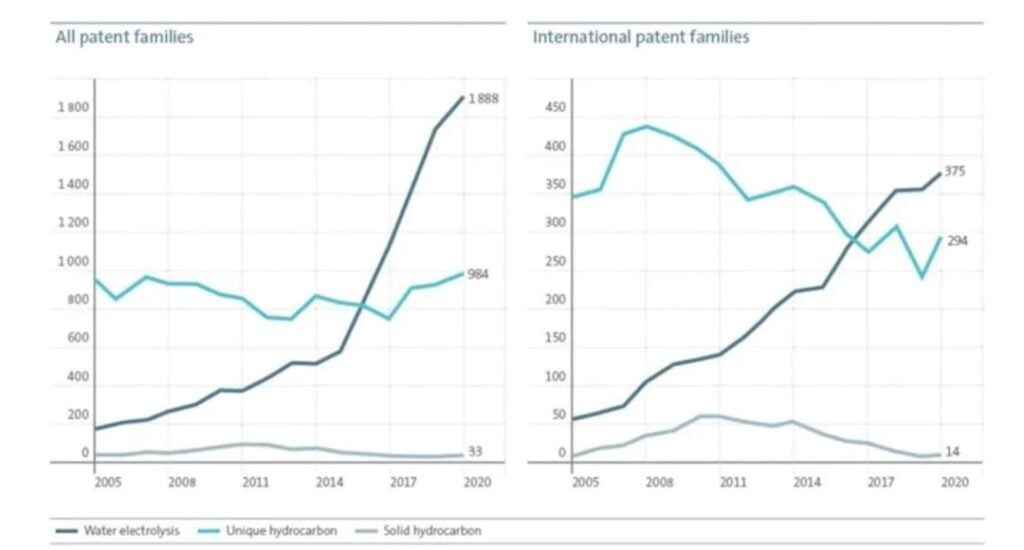

The analysis shows that patent applications for hydrogen production technologies have grown at an average rate of 18% per year since 2005. It much faster than most technologies in the energy sector. In 2016, the number of international patents for electrolytic water technologies exceeded the number of patents related to hydrogen production from fossil energy sources (Figure 1).

Figure 1: This figure shows the trend of patent families (left) and international patent families (right) from 2005-2020. Comparing hydrogen production processes based on water electrolysis with those using liquid or solid hydrocarbon feedstocks.

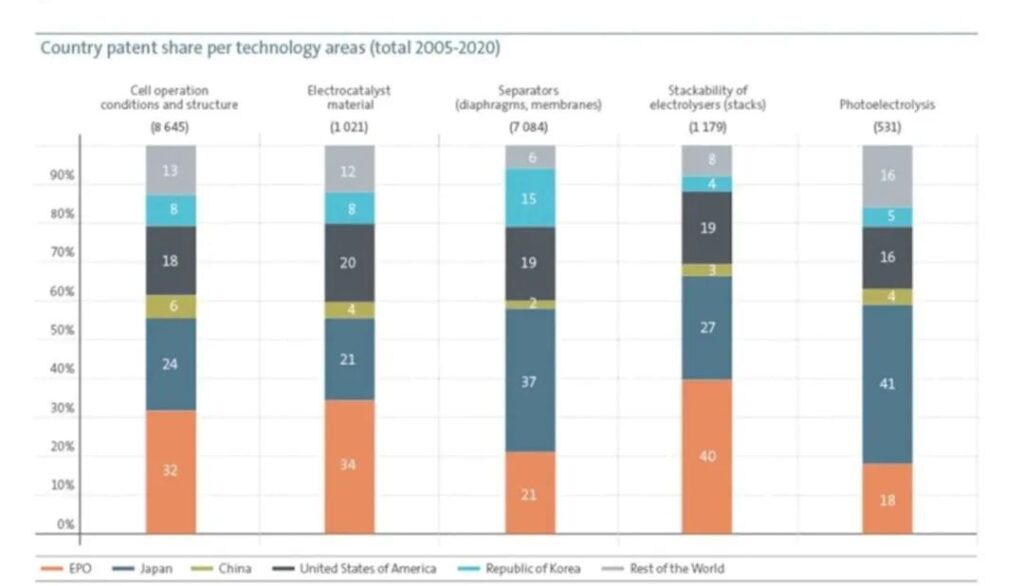

The report also analyzes five subtechnologies related to electrolytic water. That are important for reducing the cost of electrolytic cells (Figure 2).

Five sub-technologies related to electrolysis of water:

1. Cell operating conditions and structure: High temperature and high pressure operating conditions. It required to improve the efficiency of the electrolyzer without compromising the life. And the performance of the membrane, and also to control costs.

2. Electrocatalytic materials: The scarcity of materials is an important obstacle to the cost and scale-up process of electrolyzer. And alternative materials need to be sought to solve this problem, such as using non-precious metal materials.

3. Separation membranes (diaphragms, membranes): reducing membrane thickness can increase efficiency and thus reduce power consumption.

4. Stackability of electrolytic baths: Electrodes, bipolar plates and porous transport layers can significantly increase stacking costs. Improvements in these components, including their fabrication, can reduce costs.

5. Photodissociation: Photodissociation can integrate the production of electricity and hydrogen in a single step. It may be cost-effective, but currently faces challenges of technology maturity and low pathway efficiency.

Some important findings include the fact that the number of inventions of relatively inexpensive mineral material electrocatalysts exceeded the number of inventions of traditionally expensive electrocatalysts (using, for example, gold, silver, platinum or other precious metals) in 2018. Confirming the push for cheaper alternative catalytic materials.

Photoelectrolysis, the decomposition of water into hydrogen and oxygen using light as an energy source, is an emerging and powerful technology with an above-average number of international patent applications, about 50% of which are filed by universities.

In terms of geographic location, Europe and Japan lead the way. It accounts for more than 50% of the total number of international patents filed in all five sub-technology areas.

Which countries have a high number of international patent applications?

Sub-technologies leading the number of patent applications in Europe: stackability of electrolytic cells (40%). Electrocatalyst materials (34%) and cell operating conditions and structures (32%);

sub-technologies leading the number of patent applications in Japan: photolysis (41%) and membranes (37%).

The average share of the U.S. in the number of patent applications in all technology areas is 18%, while Korea has the highest share in membranes (15%), while the average share in other categories is 7%.

China’s average share of international patents in these five technology areas is about 4%. But it dominates in terms of purely domestic patent filings.

The tremendous momentum observed in the electrolyzer is expected to continue and spur future innovation. In fact, the upward trend in patent filings indicates that more patent applications are coming. And that there is an urgent need to address issues such as electrolyzer cost, efficiency and production at scale.

The demand for renewable hydrogen has never been greater. And major innovations in electrolysis technology still need to be worked on to make the technology market ready at the industrial level.

Innovation in the field of electrolysis tanks is a widely recognized strategy to make hydrogen production. Cost-competitive with other technologies and as environmentally friendly as possible. Thus helping to address challenges such as decarbonization and accelerating the energy transition.