At present, hydrogen production mainly contains four processes and technologies:

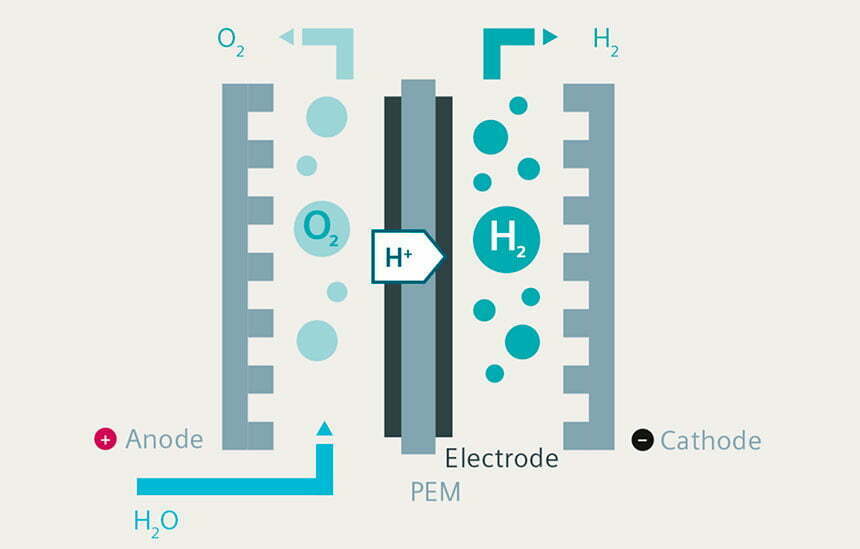

1. Electrolysis of water;

2. Fossil fuels;

3. Industrial by-products;

4. Biomass.

Electrolysis of water can directly obtain fuel hydrogen without CO, but its high cost is not conducive to the widespread promotion of this technology. Although the cost of the three types of production technologies such as fossil fuel hydrogen production is relatively low. Because the produced hydrogen is not fuel hydrogen, we cannot use the obtained hydrogen. The main reason is that CO is inevitably produced during the production process and must go through the subsequent separation and purification process before it can be used in fuel cells.

At present, the industry usually uses the pressure swing adsorption method to separate and purify hydrogen. However, this method has a complicated process, high energy consumption, and needs to provide a higher pressure during the purification process, which places high requirements on the safety of the entire hydrogen production process.

The use of membrane separation technology can couple reaction and separation to directly obtain CO-free hydrogen in one step. It is easy to integrate later, and has a small investment and floor space. It is a more economical and promising hydrogen separation technology.