The new hydrogen fuel cell technology delivers up to 50 percent more performance than current state-of-the-art technology. And durability has been improved. Advances in trench electrode design may help optimize next-generation fuel cell technology to power zero-emission medium- and heavy-duty transportation.

“Battery performance improved by redesigning the electrode structure,” says Jacob Spendelow, a materials scientist with the Los Alamos National Laboratory team. He describes his findings in the journal Nature Energy. “One of our biggest takeaways is that novel materials are not the only way to improve performance. The way the materials are combined is just as important.

“What we’ve done is take traditional commercially available materials and change the way we put them together to change the microscale architecture to significantly improve performance.”

Hydrogen fuel cells – particularly proton exchange membrane fuel cells – represent an emission-free power design using hydrogen as fuel. Fuel cells could transform the medium- and heavy-duty transportation sector, which has struggled to decarbonize.

Designed for efficiency and durability

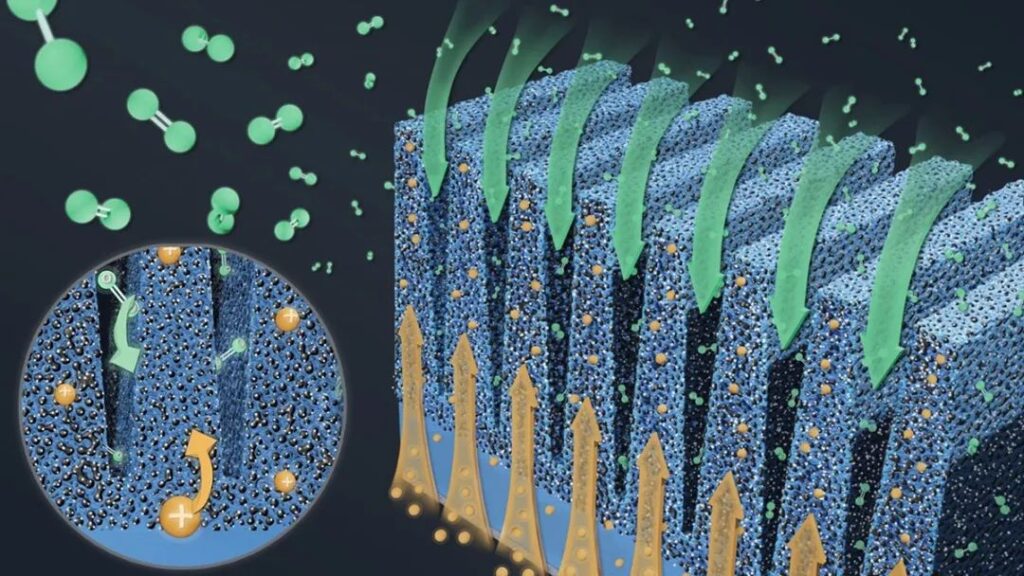

In a fuel cell device, hydrogen and oxygen undergo an electrochemical reaction to produce electrical energy. The electrochemical reaction occurs within the fuel cell electrodes, which include a platinum-based catalyst to effect the reaction and an ion-conducting polymer (ionomer) to transport the protons needed to complete the reaction.

Spendloe and colleagues in the lab developed a grooved electrode design that improves oxygen and proton transport efficiency. The team used photolithography and micron-scale deep reactive ion etching to pattern silicon templates for electrode fabrication. The resulting electrodes consist of catalyst ridges with high ionomer content separated by empty grooves. The structure facilitates the rapid transport of protons and oxygen.

The team’s design combined with multi-physics field modeling and simulation demonstrated improved oxygen transport. Machine learning accelerated the multi-physics field modeling calculations, thus saving computational time. Notably, the grooved electrodes remained highly durable even after carbon corrosion.

History of Innovation

The notched electrode approach is one of several novel fuel cell designs that have initiated by the Los Alamos Fuel Cell Program.

“The original fuel cell membrane electrode assembly invented at Los Alamos more than 30 years ago, but little has changed in the design of the fuel cells in use today,” Spendloe said. “This grooved electrode is one of the first alternative electrodes that can replace the historic Los Alamos electrode.”