Hydrogen as a clean, renewable green energy has become the future trend, how to make hydrogen is a problem, at present the proton exchange membrane electrolysis of hydrogen is one of the main methods of producing hydrogen, the technology will be proton exchange membrane as a solid electrolyte to replace the alkaline electrolyte and diaphragm, and pure water as the electrolyte, with a compact device, the preparation of high purity of hydrogen, high security, does not produce harmful impurities It is characterized by compact device, high purity of prepared hydrogen, high safety, no harmful impurities, clean and environmental protection, etc.

The membrane electrode consisting of Gas Diffusion Layer (GDL), catalytic layer and proton exchange membrane is the main place for electrochemical reaction in PEM electrostacks, and is the core component of PEMWE.

The diffusion layer not only supports the Catalyst Coated Membrane (CCM), evenly distributes the reaction water, and discharges the generated gas in time, but also realizes the function of current conduction, which is one of the key components affecting the performance of hydrogen production in PEMWE.

A good diffusion layer material should have the following characteristics:

(1) good electrical and thermal conductivity, the contact resistance between the electrode catalyst can be kept at a low level to reduce the electrolytic overpotential;

(2) strong acid corrosion resistance, as the anode of the diffusion layer in order to overcome long-term contact with the oxygen precipitation reaction should have good resistance to oxidation corrosion, while the cathode diffusion layer in order to overcome long-term contact with the hydrogen precipitation reaction should be resistant to hydrogen embrittlement;

(3) porous and flexible, because the diffusion layer is close to both sides of the membrane electrode, playing a supporting role of the membrane electrode, so it can withstand a certain pressure;

(4) Longer service life and cheaper.

Comparing titanium felt, sintered titanium plate, carbon paper and other materials as anode diffusion layer, it is found that ti felt has the best electrolytic performance, the smallest ohmic resistance, good stability, so titanium felt is more suitable as anode diffusion layer for PEMWE.

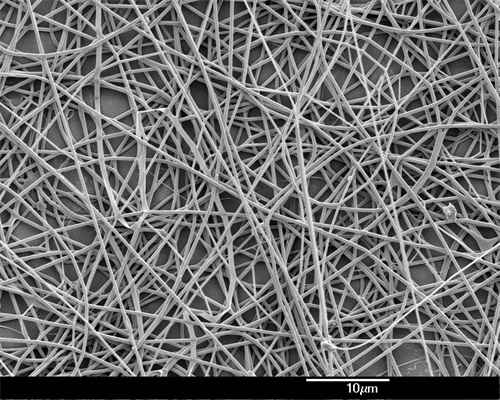

The titanium felt for gas diffusion layer sintered mat developed by raytron is made of micron-sized pure titanium fibers through a special matting process and ultra-high temperature vacuum sintering process. Titanium fiber felt has excellent three-dimensional mesh porous structure, high porosity, large specific surface area, uniform pore size distribution, strong corrosion resistance, good water permeability, good heat dissipation, high current density, low voltage, stable performance, long life and other advantages. Widely used in fuel cells, military, aerospace, civil, medical and other industries. Especially for hydrogen fuel cell diffusion medium: for anode diffusion layer (GDL) in proton exchange membrane (PEM) water electrolysis. Titanium felt needs of enterprises or research institutes, you can contact us directly, raytron can be customized according to customer requirements to produce a variety of specifications, performance of titanium fiber felt, there are postgraduate students need titanium felt samples, we can also provide free help test.