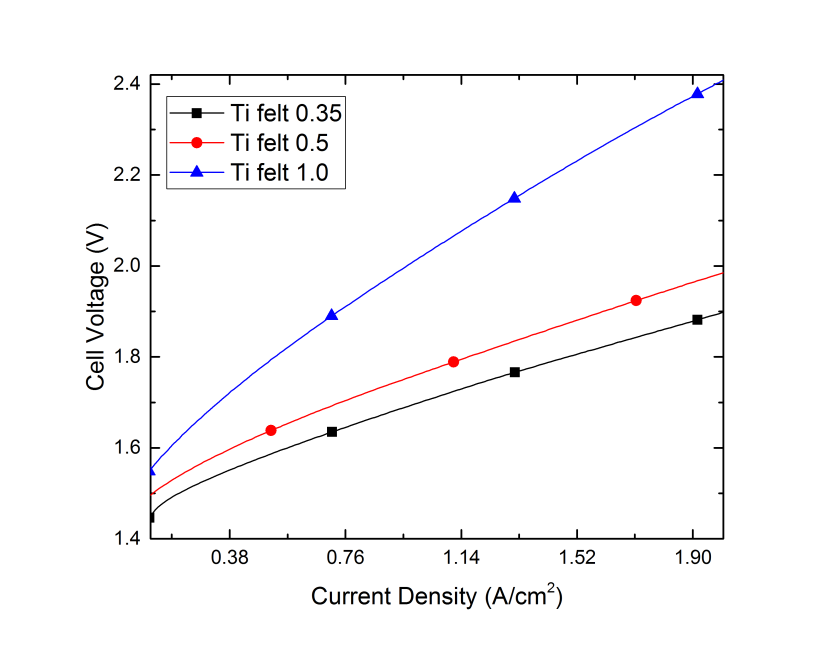

Titanium felt LGDL Performance comparison

PEMEC tests were performed with 20ml/min flow rate of liquid water at the anode side and 80 degrees temperature; the performance and impedance results shows in Figure about titanium felt, respectively.

(square: 350 um thickness; circle: 500 um thickness; triangle: 1000 um thickness)

With the further research, among three different thickness titanium LGDLs in Figure. It shows that the PEMEC with a 350 micron thickness titanium LGDL has the best performance. And then, the next best performing : the PEMEC with a 500 micron thickness titanium. Finally, for the worst one: the PEMEC with a 1000 micron thickness titanium felt.

Finally, at a current density of 2.0 A/cm, the cell voltage reduced from 2.41V with a 1000 micron thickness ti felt LGDL to 1.90V with a thinner one of 350 micron thickness ti felt LGDL.

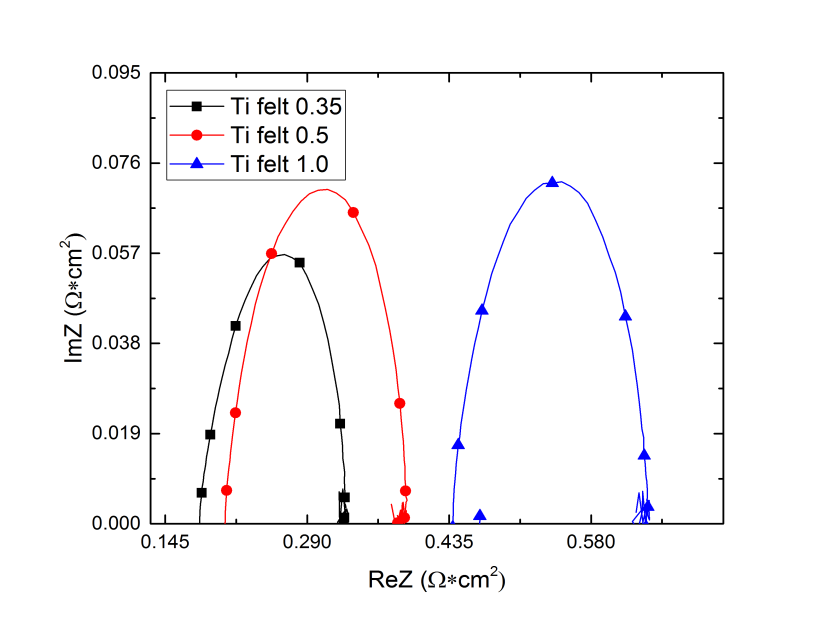

Titanium felt LGDL GEIS comparison

Under 80 degrees temperature and 2.0 A/cm current density, the scanning frequency is 10 mHz to 15 kHz in the performance test. GEIS was performed on cells with different thicknesses of titanium felt LGDL.

(square: 350 um thickness; circle: 500 um thickness; triangle: 1000 um thickness)

As we can see, a Nyquist plot of GEIS result in Figure. With the further research, the solution resistance is available by reading the real axis value at the high frequency intercept. At the other (low frequency) intercept. The real axis value is the sum of the polarization resistance and the solution resistance. The diameter of the semicircle is therefore equal to the polarization resistance. From the Figure, it shows that the PEMEC with a 350 micron thickness ti LGDL has the smallest electrical resistivity. Secondly, the next is the cell with a 500 micron titanium LGDL. Finally, the cell with a 1000 micron thickness ti felt LGDL has the largest electrical resistivity.

Finally, these results indicate that the contribution of the thickness of ti felt LGDL on the performance of PEMEC might be mainly due to the ohmic over potential. With a thicker titanium felt LGDL, the PEMEC has the larger electrical resistivity. It will make for greater ohmic overpotential, and consequently worse performance in PEMECs.

From 《Investigation of titanium felt transport parameters for energy storage and hydrogen/oxygen production》DOI:10.2514/6.2015-3914